Implementing Sustainable Practices in Asphalt Mining

Client Overview

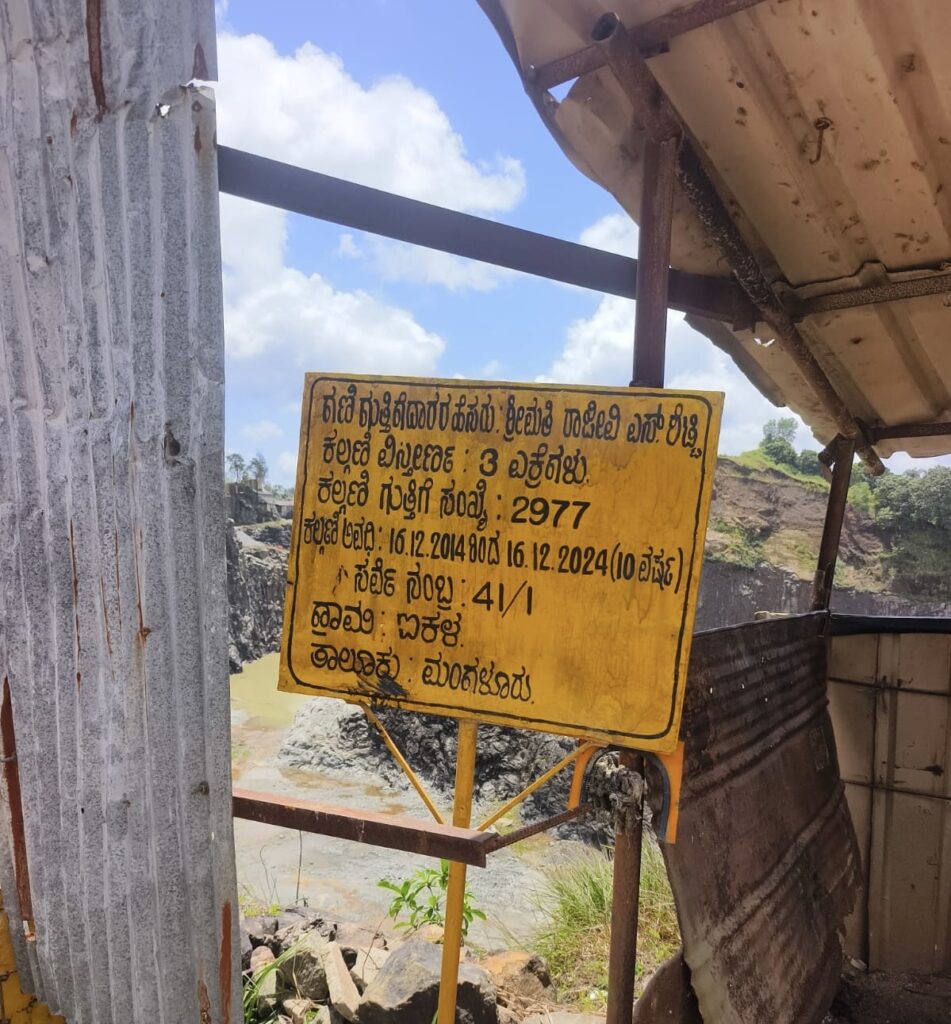

Industry: Mining (Asphalt)

Location: Mangalore, India

Scope of Operations: Asphalt mining and processing

This case study documents the transformation of a Mangalore-based asphalt mining company toward more sustainable practices. The company’s objective was to reduce its environmental impact, enhance worker safety, and improve operational efficiency. We collaborated to implement sustainable measures in raw material use, energy consumption, waste management, worker safety, and transportation, resulting in measurable improvements.

Asphalt, also known as bitumen, is a dark, sticky, and highly viscous material derived from the refining of crude oil or through natural deposits. Asphalt’s most common use is in road construction, where it acts as a binder for aggregates, forming a strong and flexible surface layer. Asphalt is widely used in roofing, where its water-resistant properties help protect buildings from moisture. This makes asphalt shingles a popular choice in various climates. Asphalt’s ability to create robust, flexible, and waterproof surfaces makes it indispensable in building and maintaining essential infrastructure.

The industry is now moving towards more sustainable asphalt processing practices, which aim to reduce the environmental footprint of asphalt use through recycling, lower energy consumption, and eco-friendly alternatives.

Challenges

The client faced several key challenges typical in the mining industry:

- High energy consumption and reliance on non-renewable energy sources.

- Inefficient raw material usage, leading to waste and higher operational costs.

- High levels of dust emissions impacting local air quality and worker health.

- Limited byproduct utilization, with potential revenue being lost.

- Worker safety and well-being concerns, including a need for more structured health programs.

- Environmental impact from uncovered transport of mined rocks.

Objectives

- Enhance safety standards and worker health

- Reduce dust emissions and improve air quality

- Decrease energy consumption and explore renewable options

- Implement closed-loop systems to minimize waste

- Repurpose byproducts to reduce raw material dependency

- Develop structured programs for worker training and well-being

Interventions and Methodology

Covered Transportation Vehicles

Problem analysis

Uncovered trucks transporting mined rocks generated high dust levels along transport routes, negatively affecting nearby communities and resulting in frequent complaints. Initial measurements showed that dust levels above the truck beds were significantly high, contributing to particulate pollution along the routes.

Data collection

To mitigate dust emissions, a policy was implemented requiring all trucks transporting rocks to be covered.

This measure aimed to contain dust directly at the source—above the truck beds—preventing it from spreading to surrounding areas and impacting nearby communities.

Methodology

Dust levels above the truck beds were measured before and after the intervention to assess the effectiveness of the covering policy.

Conclusion

Before: Initial measurements of dust above the uncovered trucks indicated elevated levels, with particulate readings reaching 200 µg/m³.

After: After implementing the covered truck policy, dust levels above the truck beds decreased by 70%, with readings reduced to 60 µg/m³. This reduction highlighted the effectiveness of the covering intervention in directly controlling dust emissions and reducing particulate pollution along transport routes.

Water spraying

Problem analysis

Dust emissions from various areas within the mining site, including high-traffic routes, loading and unloading zones, and exposed surfaces, were contributing to elevated particulate levels in the air.

Data collection

Dust levels were monitored using handheld dust monitors placed in key areas, such as roads, loading zones, and high-traffic routes, to track the airborne particulate levels before and after the implementation of water-spraying mechanisms.

Methodology

- Airborne particulate levels in high-traffic areas and exposed surfaces were consistently elevated, with readings indicating a significant amount of dust in the air. Preliminary analysis indicated that dust particles were easily becoming airborne due to dry, exposed surfaces and heavy vehicle movement.

- Water-spraying systems were installed along high-traffic routes and dust-prone areas. These systems periodically sprayed water on road surfaces and exposed areas to reduce airborne dust. Monitoring was continued for another two weeks after the installation of the water-spraying mechanisms to assess their effectiveness.

Conclusion

- Dust emissions around the site dropped by 25%, with air quality improving significantly, reaching a level compliant with local regulatory standards.

- Particulate levels went from 120 µg/m³ to 90 µg/m³, measured through regular air samples

Reducing Dust Emission using a cloth

Problem analysis

In this study, we focused on the particulate emissions generated by mining operations, particularly PM10 and PM2.5, which are known to pose the greatest health risks. In the given case, dust levels from mining exceeded safe limits by 20%, with recorded particulate matter (PM) at 120 µg/m³.

PM10 and PM2.5 are both categories of particulate matter defined by their size. PM10 refers to particles with a diameter of 10 microns or less, and PM2.5 refers to those with a diameter of 2.5 microns or less.

Data collection

Weekly air quality readings were taken at key points within the mining area and along high-traffic routes that were likely to be affected by dust emissions, particularly areas near truck loading zones, processing units, and haul roads.

Methodology

- Data was recorded for a period of several months to capture seasonal variations and identify patterns in dust levels linked to mining activity, traffic patterns, and weather conditions.

- Cloth materials were installed on the mining belt and tied to the trucks during loading. This helped contain the dust and prevented it from spreading during transport, significantly reducing the amount of dust that escaped into the air.

Conclusion

After the implementation of the dust control measures, there was a notable improvement in air quality around the mining site:

- Particulate Levels: The particulate matter (PM) levels dropped from 120 µg/m³ to 60 µg/m³, a reduction of 50%. This brought the particulate levels in line with local regulatory standards, significantly improving air quality.

Planting a green belt

Problem analysis

Mining activities often result in significant dust generation, which can negatively impact local air quality, surrounding ecosystems, and human health. To address these concerns, a sustainable and long-term solution was sought to mitigate the dust produced by mining operations and to protect nearby communities and the environment.

Methodology

A green belt was established along the perimeter of the mining site as a sustainable and natural solution for dust control. The green belt was designed to act as a barrier, trapping dust before it could spread to neighboring areas. To optimize its effectiveness, fast-growing, dense trees with large leaves were selected. Native species suited to Mangalore’s tropical climate were prioritized, ensuring sustainable growth and biodiversity benefits.

To maintain the density and health of the green belt, regular irrigation was provided, particularly during dry spells. Fertilization and pruning were performed as needed, ensuring the trees remained robust and effective as a dust barrier.

Conclusion

The establishment of the green belt around the mining site proved to be an effective and sustainable solution for dust control.

By selecting native, fast-growing tree species and providing regular maintenance, the green belt not only mitigated dust pollution but also enhanced local biodiversity, contributing positively to the ecosystem.

This initiative exemplifies how ecological solutions can be integrated into industrial practices to promote sustainability and minimize negative environmental impacts.

Covering Transportation Belts with Metal Sheets

Problem analysis

Transportation belts used in mining operations often generate significant amounts of dust as materials are moved across the site, leading to pollution along transport routes. This dust can affect air quality, harm the health of workers and local communities, and contribute to environmental degradation. A sustainable and cost-effective solution was required to mitigate dust emissions from transportation belts without disrupting operations.

Data collection

Air quality levels along the transportation routes were continuously monitored. Readings were taken at regular intervals to establish baseline data and evaluate the effectiveness of the proposed solution after implementation.

Methodology

- The method chosen to reduce dust levels along the transport belts involved installing metal covers over the transportation belts.

- This simple yet cost-effective approach aimed to physically contain the dust generated during material transport.

- The metal covers were designed to fit snugly over the entire length of the transportation belts, creating an enclosed system that would prevent dust from escaping during transit.

- The covers were made from durable materials, ensuring they could withstand the weight of materials being transported and the environmental conditions of the mining site.

Conclusion

- The installation of metal covers on the transportation belts proved to be a highly effective dust control solution.

- Dust levels along the transport routes decreased by 70%, with particulate matter concentrations dropping from an initial 200 µg/m³ to 60 µg/m³ after the metal covers were installed.

- Overall, covering transportation belts with metal covers proved to be a simple, efficient, and sustainable method for controlling dust, enhancing air quality, and promoting community well-being.

Covering Loading spouts

Problem analysis

Uncontrolled dust emissions during loading operations were a significant environmental and occupational challenge. Measurements indicated that particulate matter (PM) levels near the loading spouts reached 200 µg/m³, far exceeding safety standards. The dispersed dust affected workers’ health, air quality, and regulatory compliance.

Data collection

Before implementing the cloth covers, dust levels were monitored at multiple points around the loading spouts. Particulate matter (PM) concentrations were recorded using air quality monitors. Initial readings showed 200 µg/m³ of particulate matter.

Methodology

To address this issue, cloth covers were installed around the loading spouts to contain dust directly at the source during material transfer. This simple and low-cost intervention was implemented without disrupting operations. Workers were trained to install and secure the cloth effectively.

Conclusion

Before the intervention, dust levels near the loading spouts were at 200 µg/m³, presenting serious health and environmental concerns.

After implementing the cloth covers, dust emissions were reduced by 70%, with PM levels dropping to 60 µg/m³.

Safety and Health Programs

Problem analysis

In analyzing safety and health concerns within the client’s asphalt mining operations, a key issue emerged around the inconsistent use of protective equipment. Data indicated that, on average, only 60% of workers consistently used protective gear, leading to an estimated 15 safety incidents each year. Many workers, despite being provided with the necessary equipment, would not wear helmets, cover their faces only with cloth rather than the provided masks, and often neglected to use gloves. This lack of proper protection was a significant contributor to both respiratory discomfort and minor injuries, creating an ongoing safety challenge.

Data collection

I approached data collection by combining direct employee feedback and observation:

- Employee Feedback: Conducted informal conversations and surveys with employees to understand their reasons for inconsistent use of protective gear and any discomforts they experienced.

- On-Site Observations: Spent time on-site to observe daily practices, focusing on when and why workers did or did not wear protective gear.

Methodology

- To address these challenges, a straightforward approach was recommended to raise awareness and increase compliance.

- Small, hands-on training sessions were suggested to connect safety practices to everyday experiences. These sessions emphasized the benefits of each item, such as how masks and gloves could prevent common respiratory issues and injuries that workers often experienced firsthand.

- To make safety a collaborative effort, a simple monitoring protocol was recommended, where team leaders provided friendly reminders and helped workers with gear setup at the start of each shift.

Conclusion

Workers became more comfortable using helmets, masks, and gloves, appreciating the direct benefits to their health.

These interventions led to a 30% drop in safety incidents, reducing them to about 10 per year, as compliance with protective gear increased across the site.

Reducing discarded waste

Problem analysis

- Over-reliance on raw materials led to waste and high costs, with 2 tons of raw material discarded annually.

- Byproducts, such as rock dust, were underutilized, creating unnecessary disposal costs and harming the environment.

Data collection

Tracked where raw materials were being lost by counting leftovers and checking for unused material at different stages.

Methodology

- To track material flow and reduce waste, I recommended a simple charting method combined with manual data collection. This approach is less complex but still allows for effective monitoring and decision-making by providing clear visual insights into raw material usage and waste.

- I explored the potential for recycling the rock dust and other byproducts. Instead of being discarded, I suggested partnering with a brick manufacturer for repurposing these byproducts for use in creating bricks for construction, offering a sustainable way to reuse the material while reducing disposal costs.

I helped set up a system for monthly waste audits across different production stages. These audits focused on:

- Counting and categorizing unused or discarded raw materials.

- Tracking byproducts such as rock dust that had been traditionally discarded but could now be put to better use.

Conclusion

- Before: 2 tons of raw material discarded annually.

- After: Waste reduced to 1.5 tons, a 25% reduction.

0.5 tons of rock dust were successfully repurposed into bricks, which not only reduced the need for new materials but also prevented these byproducts from going to landfills.

Results and Impact

Through these targeted interventions, the asphalt mining company achieved substantial improvements in sustainability:

- Before the safety program enhancements, only 60% of workers consistently used protective gear, leading to an average of 15 safety incidents per year. After the improvements, compliance increased, and safety incidents dropped by 30%, reducing to about 10 incidents annually. This led to a safer working environment, fewer injuries.

- Initially, 2 tons of raw material were discarded annually. After implementing better waste management practices, this was reduced by 25%, bringing the total waste down to 1.5 tons per year. Additionally, 0.5 tons of rock dust were repurposed into bricks, reducing landfill waste and minimizing the need for new materials, making the process more sustainable.

- Particulate levels above uncovered trucks were initially recorded at 200 µg/m³. After covering the trucks, dust levels dropped by 70%, reducing particulate matter to 60 µg/m³. This resulted in a significant decrease in dust pollution along transport routes, improving air quality and ensuring compliance with air quality standards.

- Dust emissions were initially at 120 µg/m³ around the site. With the introduction of water spraying systems, dust levels were reduced by 25%, dropping to 90 µg/m³. This helped improve air quality and ensured that the site met local regulatory standards for dust control.

- Before the cloth-based solution, particulate levels were 120 µg/m³. After implementing the cloth-based dust control system, particulate levels decreased by 50%, reaching 60 µg/m³. This brought the air quality in line with local standards, significantly improving conditions for workers and the surrounding environment.

- The green belt was established to reduce dust pollution along the perimeter of the mining site. This initiative helped trap airborne dust, improving air quality and enhancing biodiversity, while providing a sustainable long-term solution for dust control.

- Dust levels along the transportation belts were initially at 200 µg/m³. After installing metal covers, dust levels decreased by 70%, reducing particulate matter to 60 µg/m³. This intervention proved highly effective in controlling dust emissions and improving air quality along transport routes.

Lessons Learned

This project has demonstrated that with the right combination of innovative, cost-effective solutions and a commitment to sustainability, mining operations can significantly reduce their environmental footprint, improve worker safety, and enhance operational efficiency. The following lessons learned will guide the company in continuing its transformation journey:

- Small Interventions Can Yield Big Results

- Simple, low-cost interventions like covering transportation vehicles with tarps or installing metal covers on transport belts proved to be highly effective in reducing dust emissions. These initiatives not only improved air quality but also showcased that sustainability doesn’t always require large investments or major overhauls. Small changes, when executed properly, can have a substantial impact.

- Data-Driven Decision Making is Key

- The success of these interventions was rooted in data-driven insights. Regular monitoring of particulate levels and waste production allowed the company to make informed decisions and track the effectiveness of each initiative. Ongoing data collection, particularly on air quality, dust levels, and waste management, will be essential for fine-tuning these solutions and ensuring continuous improvement.

- Repurposing Waste is a Win-Win

- The successful repurposing of 0.5 tons of rock dust into bricks highlighted the value of byproduct utilization. This initiative not only reduced waste disposal costs but also created a new revenue stream, contributing to the company’s sustainability goals. The lesson here is that mining operations can often find value in what would otherwise be considered waste, and exploring these opportunities can drive both economic and environmental benefits.

Future Outlook

As a sustainability consultant, I see significant potential for the company to strengthen its environmental commitments in the coming years. Key initiatives include:

- Renewable Energy Integration

- The company plans to invest in solar and wind power, reducing its reliance on non-renewable energy sources. This will lower its carbon footprint and support more sustainable mining practices.

- Circular Economy Principles

- The company will expand its efforts to implement closed-loop systems, using byproducts from one part of the operation as inputs for another. This includes recycling additional materials, such as reclaimed asphalt, to reduce waste and reliance on virgin resources.

- Road Debris Recycling Expansion

- The company will scale up its road debris recycling program, collecting and repurposing materials like broken asphalt, concrete, and gravel. This will reduce landfill use and create a circular flow of materials for new construction, further supporting sustainability goals.

- Integration of Recycled Materials in Asphalt Production

- By increasing the use of recycled asphalt and aggregates, the company can reduce raw material consumption, lower production costs, and minimize environmental impact.

Through these initiatives, the company will not only enhance its sustainability but also improve operational efficiency, positioning itself as a leader in eco-friendly mining practices.