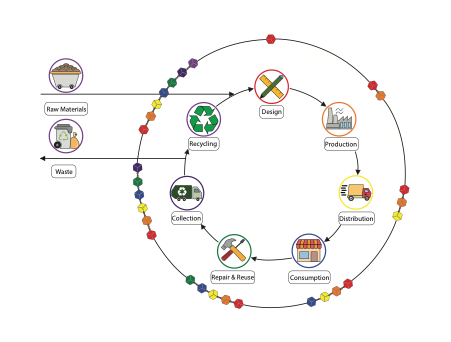

As companies shift toward circular economies, many are exploring reverse supply chains to reclaim products from customers for recycling, refurbishment, or responsible disposal. Unlike standard returns, these buy-back and recycling programs aim to close the loop in a product’s lifecycle, reducing waste and resource consumption. But despite the appeal, many companies find reverse supply chains a difficult strategy to execute. Issues like high operational costs, logistical complexities, and variable product conditions can often outweigh the benefits, resulting in programs that struggle to meet both environmental and financial goals.

The Unique Complexities of Reverse Supply Chains

While traditional logistics focus on delivering new products to consumers efficiently, reverse supply chains move goods back from consumers to manufacturers for end-of-life management. For buy-back and recycling programs, companies must account for unique challenges:

- Diverse and Unpredictable Product Condition: Returned items vary in wear and quality, which complicates recycling or refurbishment processes.

- Logistics of Collection and Transportation: Gathering used products from consumers, transporting them to processing centers, and managing these flows is expensive and resource-intensive.

- High Processing Costs: Assessing, sorting, and recycling or refurbishing products often requires additional labor, advanced technologies, and dedicated facilities.

These logistical and financial challenges, while common to all reverse logistics, are particularly pronounced in buy-back and recycling initiatives.

Real-World Examples: Companies that Have Struggled with Reverse Supply Chains

Several major brands have launched buy-back and recycling programs, only to find them more costly and difficult to manage than anticipated.

a) Apple’s iPhone Recycling Program

Apple’s iPhone recycling initiative, a part of its broader trade-in and buy-back program, allows customers to trade in their old devices for store credit, with a promise that products will be responsibly recycled. However, this initiative has proven more complex than initially expected. Apple’s goal of recovering rare earth materials and metals like lithium and cobalt from used phones is hampered by the technological limitations of current recycling processes.

While Apple introduced Daisy, a robot designed to disassemble iPhones, the technology cannot yet fully disassemble and reclaim materials at scale. The high costs of the technology and limited disassembly capabilities have meant that only a fraction of materials are successfully reclaimed, with high operational costs remaining a barrier.

b) IKEA’s Furniture Buy-Back Program

IKEA launched a buy-back program with the goal of reusing or recycling old furniture to reduce waste and promote sustainability. However, this program has encountered multiple issues. First, furniture is often heavily used or damaged, making it difficult to resell or recycle. Additionally, handling and transporting large items requires extensive resources, making it challenging to implement cost-effectively.

While IKEA has piloted the program in several countries, feedback and outcomes show it’s difficult to scale. Customers often hesitate to pay for recycled furniture, and the costs of refurbishing often outweigh the potential revenue from resale. This has led to IKEA limiting its buy-back program to certain markets, reflecting the operational complexities of reverse supply chains in the furniture sector.

c) H&M’s Textile Collection Initiative

H&M’s textile recycling initiative encouraged customers to return used garments to their stores for recycling. While the program received positive attention, it has proven unsustainable at scale. Textile recycling technology lags behind, as it’s difficult to separate and recycle blended fabrics into new, high-quality materials. As a result, many of the collected items are downcycled into lower-quality products like insulation material, rather than being reborn as new garments.

Furthermore, the cost of collecting, sorting, and processing used textiles often exceeds the benefits, especially given that recycling textile blends is still inefficient. Despite H&M’s efforts, the program has faced criticism for not meeting its recycling goals, highlighting the difficulty of managing textile reverse logistics at a global scale.

3. The Key Challenges of Buy-Back and Recycling Programs

Reverse supply chains for buy-back and recycling face a unique set of challenges:

- Technological Barriers: Limited recycling technology, particularly for complex products like electronics or blended textiles, means that companies can rarely recover materials at a quality sufficient for reuse.

- High Operational and Logistics Costs: The collection and transportation of returned items add layers of costs that are not as present in traditional supply chains.

- Environmental Trade-Offs: Although buy-back programs aim to reduce waste, the emissions generated from additional logistics and processing can sometimes offset environmental benefits.

- Consumer Engagement: For these programs to be effective, companies rely on strong consumer participation. Yet, customer buy-in is often inconsistent, making it challenging to gather products at the volumes needed for efficient recycling or refurbishment.

4. Lessons Learned and Steps Forward

While the examples above illustrate the challenges, companies are learning valuable lessons about improving reverse supply chains. Here are some practices that are proving effective:

- Developing Closed-Loop Technology: Investing in technology that can efficiently recycle products into high-quality materials is critical. For example, companies like Adidas are researching single-material products that are easier to recycle.

- Centralizing Processing Facilities: Centralized processing can help reduce costs. Companies like Best Buy have optimized their electronics buy-back program by consolidating returns at a few dedicated facilities, enabling more efficient handling and sorting.

- Consumer Education and Incentives: Increasing awareness about the importance of these programs and offering incentives can improve customer engagement, helping companies collect higher volumes and operate at a more effective scale.

- Material Innovation: Using recyclable or biodegradable materials from the beginning can reduce reverse logistics costs and improve the recyclability of products. The fashion industry, for example, is exploring single-fiber textiles to simplify garment recycling.

Conclusion: A Work in Progress

Reverse supply chains for buy-back and recycling programs hold immense potential for promoting sustainable practices. However, as IKEA, Apple, and H&M demonstrate, the challenges in cost, technology, and logistics can outweigh the benefits. To create a truly circular economy, companies must invest in new recycling technologies, adapt their designs for easier reuse, and build infrastructure to support efficient reverse logistics.

As these systems continue to evolve, companies and consumers alike will play key roles in making reverse supply chains viable. Although the journey is challenging, the future promises exciting opportunities for innovation, ultimately bringing us closer to sustainable, circular economies.